News & Events

The City of Richmond Hill to Place New Smart Battery Collection Containers with Enhanced Safety Features at Public Facilities

April 22, 2025New state-of-the-art battery recycling containers will be placed at public facilities in the City of Richmond Hill.

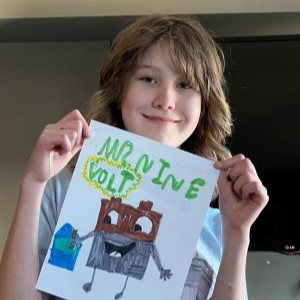

Sydney Wins the OSBRC Family Stay at Great Wolf Lodge!

April 21, 2025Sydney of Pauline Johnson Public School in Burlington is winner of this year's OSBRC Family Day prize draw for a stay at Great Wolf Lodge in Niagara Falls!

December OSBRC Student Mission Gift Card Winners!

January 16, 2025On December 6, 2024, the Ontario Schools Battery Recycling Challenge by Environmental 360 Solutions Ltd. (E360S) randomly selected five students to receive a $50 Visa gift cards.

Town of Stouffville Rolls Out Innovative Outdoor Battery Recycling Solution

November 14, 2024Environmental 360 Solutions Ltd placed its new state-of-the-art outdoor battery recycling container outside the Stouffville Town Hall at 111 Sandiford Drive.

10th Annual OSBRC Winners Named!

September 23, 2024Environmental 360 Solutions Ltd. (E360S) announced the winners of the 10th Annual Ontario Schools Battery Recycling Challenge (OSBRC).

Greater Sudbury Welcomes New SMART Battery Recycling Container from Environmental 360 Solutions Ltd.

September 18, 2024Environmental 360 Solutions Ltd installed one of its innovative smart outdoor battery recycling containers in the York Street parking lot across from Bell Park in Sudbury.

Niagara Region Embraces Innovative SMART Battery Recycling Solution

September 12, 2024Environmental 360 Solutions Ltd has introduced a state-of-the-art outdoor battery recycling container at the Niagara Region Headquarters in Thorold, Ontario.

E360S Rolls Out New Smart Battery Recycling Containers in the Municipality of Dysart et al

August 8, 2024Environmental 360 Solutions Ltd. (E360S) placed one of its new smart outdoor battery recycling containers in Dysart et al on August 8, 2024.

Environmental 360 Solutions Launches New Smart Outdoor Battery Recycling Containers in Kingston

July 11, 2024Environmental 360 Solutions Ltd. unveils its smart outdoor battery recycling containers in Kingston, Ontario, marking a significant milestone for the company and the province.

YESS Becomes a Producer Responsibility Organization for Batteries

June 18, 2024Yes Environmental Services and Solutions (YESS) is pleased to announce that effective immediately, it will provide compliance services to battery producers under the Ontario Battery Regulation 30/20 as a Producer Responsibility Organization (PRO).